ACM Aluminum Composite Material

DESCRIPTION

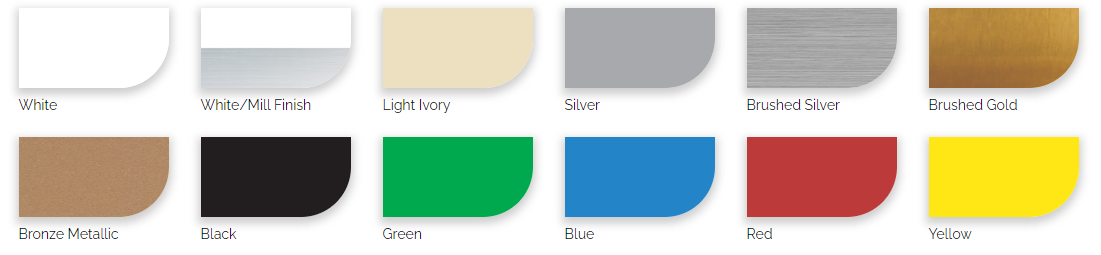

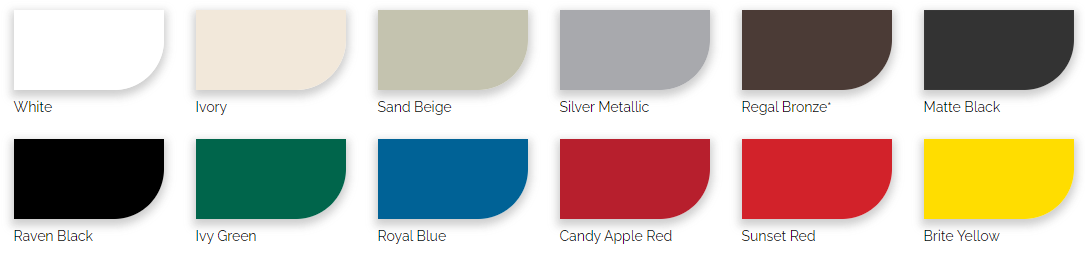

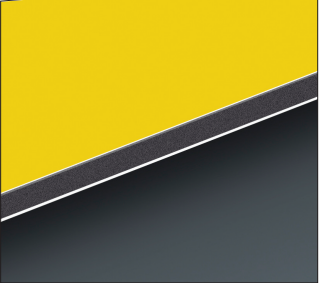

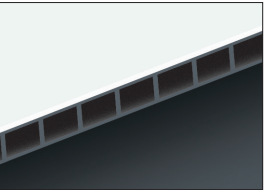

ACM sign sheet is the perfect high-quality sheet for the sign supply industry. The sheet is a sandwich construction of aluminum skins bonded to a plastic core. The aluminum sheet is a baked enamel of various sign colors and metallic finishes. The plastic core can be either solid polyethylene or a corrugated fluted polypropylene. Selection provides for a variety of thicknesses in the core and the gage of the aluminum skin. Laminators brands the solid core sheet as Omega-Bond® and the fluted core sheet as Alumalite®.

PRIMARY SOURCE

About the supplier:

Laminators, Inc. is a primary source of ACM stock sheet

Omega-Bond® Available Sizes & Colors:

| Thickness (mm) | Finished Faces | Sizes (ft) | Colors | Weight/Sq. Ft. (lbs) |

|---|---|---|---|---|

| Omega-Bond Economy | ||||

| 3 | 2 sides | 4' x 8' | White Gloss/White Matte | 0.64 |

| Omega-Bond Premium | ||||

| 3 | 2 sides | 4' x 8', 5' x 10' | White | 0.8 |

1 side is White/Mill finish. Colors and other sizes available by special order.

| Thickness (mm) | Finished Faces | Sizes (ft) | Colors | Weight/Sq. Ft. (lbs) |

|---|---|---|---|---|

| Omega-Bond Economy | ||||

| 3 | 2 sides | 4' x 8' | White Gloss/White Matte | 0.64 |

| Omega-Bond Premium | ||||

| 3 | 2 sides | 4' x 8', 5' x 10' | White | 0.8 |

Colors and other sizes available by special order.

Omega-Bond Standard (5-year Warranty)

Alumalite® Available Sizes & Colors:

| Thickness (mm) | Finished Faces | Sizes (ft) | Colors | Weight/Sq. Ft. (lbs) |

|---|---|---|---|---|

| Alumalite Standard | ||||

| 6 | 1 or 2 sides | 4' x 8', 4' x 10', 5' x 8', 5' x 10' | Standard Colors, White | 0.67 |

| 10 | 1 or 2 sides | 4' x 8', 4' x 10', 5' x 8', 5' x 10' | Standard Colors, White | 0.88 |

Custom colors and sizes available by special order.

| Thickness (mm) | Finished Faces | Sizes (ft) | Colors | Weight/Sq. Ft. (lbs) |

|---|---|---|---|---|

| Alumalite Economy | ||||

| 3* | 1 or 2 sides | 4' x 8' | White | 0.5 |

| 5 | 1 or 2 sides | 4' x 8' | White | 0.52 |

| 10** | 1 or 2 sides | 4' x 8' | White | 0.68 |

*Previously D-Lite. **Previously Pro-Lite.

| Thickness (mm) | Finished Faces | Sizes (ft) | Colors | Weight/Sq. Ft. (lbs) |

|---|---|---|---|---|

| Alumalite Ultra | ||||

| 15 | 2 sides | 4' x 8' | White | 1.4 |

| 25 | 2 sides | 4' x 8' | White | 1.81 |

1 side, colors, and other sizes availablle by special order.

Alumalite Standard and LusterBoard (10-Year Warranty)

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields