PET-G Polyethylene Terephthalate Glycol

DESCRIPTION

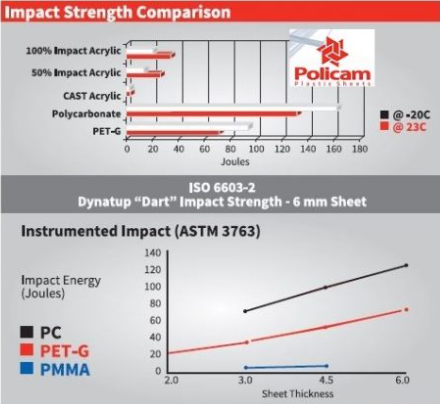

Polyethylene terephthalate glycol, more commonly called PET-G, is a thermoplastic polyester that provides significant chemical resistance, durability, and excellent formability for manufacturing. Generally, PET-G is clear and in sheet form and is used as an alternative to acrylic and polycarbonate.

PET-G is very easily CNC routed, vacuum formed, as well as line-bent due to its low forming temperatures. PET-G is selected over acrylic due to greater impact resistance and in some instances can be down gaged to save cost. With the greater impact, PET-G is softer so scratches more easily than acrylic. PET-G is naturally food safe, making it a good option for trays or displays around food.

Meyer Plastics stocks PET-G sheets in several gages and is experienced in fabricating this material into many different displays, covers, and OEM parts. For large orders custom sizes can be provided.

PRIMARY SOURCE

About the supplier:

Sirius is our primary source for PET-G Sheet

About the supplier:

Primex Plastics is also a primary source

PETG Properties

- Very high impact resistance

- Excellent transparency and gloss

- Cost effective

- Easy to fabricate

- B1/Class 1Y fire rated

- Suitable for food contact

- Can be cut with laser and with a shear

- Surface scratches can easily be removed

- 89% light transmission

- Superior chemical resistance

- Lower cost alternative to polycarbonate

- Deep thermoforming capability

- Low non-toxic smoke generation

- FDA Tested - Food contact

- Max continuous operating temp 149 F

- Max intermittent operating temp 162 F

For your complex shapes and deep draw forming needs where you hesitate to use acrylic, we offer you PETG sheets. 15 times

tougher than acrylic, our PETG sheets are ideal for most demanding uses.

PETG sheets are used for the

vending machine graphics. They are a superhero combining clarity with toughness, chemical resistance with fire safety and printability with deep draw formability.

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields