Polycarbonate (Lexan)

DESCRIPTION

Polycarbonate, PC, is the go-to clear substrate for security applications. Due to its excellent impact toughness, it can be fabricated into sales counter shields, machine guards, riot shields and containment vessels. At room temperature it can be easily cold formed with a press break. Injection molded polycarbonate is the plastic used for every eyeglass lens and automobile headlight. Without protection from UV rays, it is vulnerable to yellowing, as can be seen on many older cars. PC requires an additive or coating for long term UV exposure. It can also be treated with abrasion resistant, AR, coating to resist scratching. For bullet proof glazing, polycarbonate sheet is laminated for extreme security situations. Polycarbonate is available in an array of sheet gages, sizes, and colors. Next time you want to solve a security issue, call Meyer Plastics to add impact to your project!

NOTE: Lexan® is the number one brand for polycarbonate. So successful, the brand is better known than the generic name, polycarbonate. We supply Palsun® UV2 made by Palram Americas. UV2 designates Ultraviolet protection on both sides of the sheet. We also supply Polycarbonate sheet from Gallina branded PoliComp®. Both are manufactured in the USA.

Meyer Plastics has extensive experience fabricating and forming polycarbonate products to our customer specifications. We are available for project planning, sampling for feasibility, and prototype parts to prove new production concepts.

PRIMARY SOURCE

About the supplier:

Palram Americas is our primary source of polycarbonate sheet.

About the supplier:

Gallina USA is also a source for polycarbonate sheet.

Available Palram Polycarbonate Types:

- Palsun® UV1/UV2/Basic: One side/Two side/Not treated

- Palsun® FR: Fire Rated

- Palsun® CS: Coil Stock

- Palsun® SG: Sign Grade, White

- Palsun® OG: Optical Grade

- PalGard® AR1, AR2 Abrasion Resistant One Side, Two Sides

- Palshield® UL1, UL2, UL3 Bullet Resistant .75”, 1.0”, 1.5” Thick

Gallina Sheet Sizes:

- Gage: .060 to .500 inches

- Sheet: 48 x 96, 60 x 96, 72 x 96, 80 x 120 inches

- Custom Lengths available

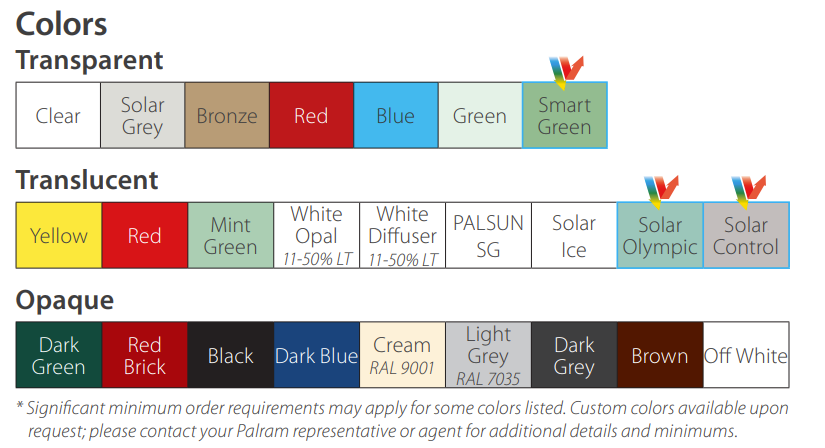

- Colors: Clear, White, Bronze, Gray, Custom w/mins.

Note: Most Palsun® sheet applications use clear sheets. Gray and bronze tint are available as is white for sign applications and black for display applications. The rest of the colors require a custom run of 6000 lbs.

Golf Cart Windshield: these windshields were CNC routed and heat line bent. They will withstand the impact of a 350-yard going for glory drive. They can be coated with an AR coating for long lasting beauty.

Gaming window for the new Chimpanzee exhibit at the Indianapolis Zoo. Meyer Plastics collaborated with their staff to deliver a design that will keep the spectators safe and minimize damage to the game electronics within the harsh chimp environment. CNC Routed both acrylic and Palsun polycarbonate. Laminated with 2-part epoxy glue.

Machine Guard made by CNC routing the center piece and two ends. Then heat line bending the center and gluing the ends to the center.

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields