Nylon PA Polyamide

DESCRIPTION

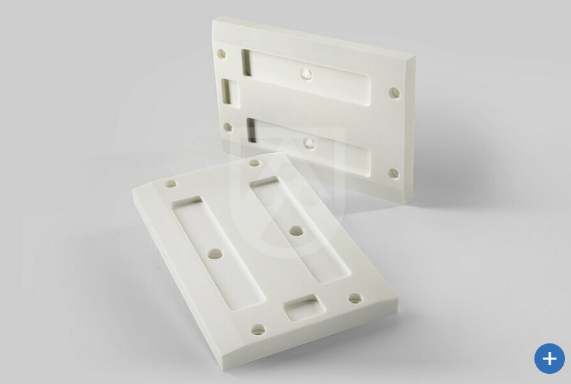

Nylon is a common synthetic plastic material composed of polyamides of high molecular weight. It was developed in the 1930s by a research team working for E.I. du Pont de Nemours & Company. Nylon is a versatile material used in everything from stockings and toothbrush bristles to industrial wear components such as bushings, bearings, and gears. One of the first successful commercial plastics, development was directed to wartime purposes during WWII in the form of parachutes and tents. Today it is still heavily used in the fabric industry with many high-performance applications like extreme outer clothing, and ballistic nylon for luggage, back packs, belts, and many more.

Nylon is known as the workhorse of the industry due to its toughness. Nylon can be processed in different ways, injection molded, extruded or cast. Nylon is naturally FDA, USDA and dairy compliant. Nylon lends itself to additives to enhance its physical properties. Common fillers used in Nylon are glass fibers, oil and molybdenum disulfide (MD). Reach out to Meyer Plastics, our inventory is full of Nylon in various stock shapes. We will also cut-to-size stock sheet, rod or tube to the dimension you require, which means we have a large inventory of cutoffs readily identified in our inventory. Maybe you need a fabricated or machined part, we can do that too. Not to be out done, we even can 3D print your design from a selection of Nylon resins including, with carbon fiber. At Meyer Plastics we can be your partner for successful project sourcing.

PRIMARY SOURCE

About the supplier:

Roechling SE & Co. is our primary source of Nylon stock shapes.

About the supplier:

Cast Nylons is also a primary source for Nylon shapes.

Primary Nylon Grades: Nylon 6, Nylon 66, Nylon 12, Nylon MD

Additional Nylon Blends: Oil infused (green), Heat Stabized (blue)

Note: Nylon MD is typically black and is often call Nylatron ®MD in the trade due to the successful marketing of Quadrant Engineering Plastics.

Type | 6 Ext | 6 Cast | Blue Cast | MD Ext | MD Cast | Green |

Rod | .125-3.00 | 2.50-3.00 | 1.00-7.00 | .188-1.75 | 2.00-10.0 |

|

Sht 24×48 | .031-1.25 | .250-3.00 | .250-3.50 | .031-.250 | .250-2.50 | .75-1.00 |

Typical Properties of Nylon 6

| Property | Units | ASTM Test Method | NYCAST 6PA Natural |

|---|---|---|---|

| Specific Gravity | g/cm³ | D 792 | 1.15 - 1.17 |

| Tensile Strength | psi | D 638 | 10,000 - 13,500 |

| Tensile Elongation | % | D 638 | 20 - 55 |

| Tensile Modulus | psi | D 638 | 400,000 - 550,000 |

| Compressive Strength | psi | D 695 | 13,500 - 16,000 |

| Compressive Modulas | psi | D 695 | 325,000 - 400,000 |

| Flexural Strength | psi | D 790 | 15,000 - 17,500 |

| Flexural Modulus | psi | D 790 | 420,000 - 500,000 |

| Shear Strength | psi | D 732 | 10,000 - 11,000 |

| Notched Izod Impact | ft.lbs/in. | D 256 | 1.5 - 2.5 |

| Hardness, Rockwell | R | D 785 | 110 - 115 |

| Hardness, Shore | D | D 2240 | 78 - 84 |

| Melting Point | °F | D 3418 | 430 ± 10 |

| Coefficient of Linear Thermal Expansion | in./in./°F | D 696 | 5.0 x 10⁻⁵ |

| Deformation Under Load | % | D 621 | 0.5 - 2.5 |

| Deflection Temperature | |||

| 264 psi | °F | D 648 | 200 - 300 |

| 66 psi | °F | D 648 | 300 - 400 |

| Continuous Service Temperature | °F | 230 | |

| Intermittent Service Temperature | °F | 330 | |

| Coefficient of Friction, Dynamic | D 1894 | 0.26 | |

| Water Absorption | |||

| 24 hours | % | D570 | 0.5 - 0.6 |

| Saturation | % | D 570 | 4.0 - 6.0 |

| Dielectric Strength | v/mil. | D 149 | 500 - 600 |

| Dielectric Constant | |||

| 60 Hz | D 150 | 3.7 | |

| 1000 Hz | D 150 | 3.7 | |

| 1 MHz | D 150 | 3.7 | |

| Compliance | |||

| FDA | X | ||

| USDA 3A | X | ||

| UL 94 HB | X |

Nylon 12

Nylon 12 is comparable to nylon 6 with higher tensile elongation and impact strength than standard cast nylon. It has superior dimensional stability and lower water absorption, making it an ideal choice in a variety of harsh environments. that require an extra degree of toughness, like ball valve seats in the oil & gas industry.

| Property | Units | ASTM Test Method | NYCAST CP 6/12 |

|---|---|---|---|

| Specific Gravity | g/cm³ | D 792 | 1.10 - 1.13 |

| Tensile Strength | psi | D 638 | 9,000 - 11,000 |

| Tensile Elongation | % | D 638 | 25 - 40 |

| Tensile Modulus | psi | D 638 | 375,000 - 475,000 |

| Compressive Strength | psi | D 695 | 12,000 - 14,000 |

| Compressive Modulus | psi | D 695 | 275,000 - 375,000 |

| Flexural Strength | psi | D 790 | 13,000 - 16,000 |

| Flexural Modulus | psi | D 790 | 325,000 - 475,000 |

| Shear Strength | psi | D 732 | 7,500 - 9,000 |

| Notched Izod Impact | ft.lbs/in. | D 256 | 2.0 - 4.0 |

| Hardness, Rockwell | R | D 785 | 100 - 110 |

| Hardness, Shore | D | D 2240 | 74 - 80 |

| Melting Point | °F | D 3418 | 400 +/- 10 |

| Coefficient of Linear Thermal Expansion | in./in./°F | D 696 | 4.0 - 5.0 x 10^-5 |

| Deformation Under Load | % | D 621 | 1.0 - 3.0 |

| Deflection Temperature | |||

| 264 psi | °F | D 648 | 200 - 300 |

| 66 psi | °F | D 648 | 300 - 400 |

| Continuous Service Temperature | °F | 210 | |

| Intermittent Service Temperature | °F | 300 | |

| Coefficient of Friction, Dynamic | D 1894 | 0.26 | |

| Water Absorption | |||

| 24 hours | % | D 570 | 0.2 - 0.3 |

| Saturation | % | D 570 | 3.0 - 5.0 |

| Dielectric Strength | v/mil. | D 149 | 500 - 600 |

| Dielectric Constant | |||

| 60 Hz | D 150 | 3.7 | |

| 1000 Hz | D 150 | 3.7 | |

| 1 MHz | D 150 | 3.7 |

Nylon MD (Nylatron MD®)

Nylon 6 material with the additive molybdenum disulfide (MoS2), creates a higher crystalline product with improved mechanical properties and built-in lubrication. Cast Nylon brands this product NYCAST 6PA MoS2 and it delivers improved wear resistance and compressive strength over the standard grade 6PA, while also adding dry lubrication benefits. Nylatron MD is the most common brand known and used in the industry and owned by Quadrant. Nylon MD is typically black.

| Property | Units | ASTM Test Method | NYCAST® 6PA Mos₂ |

|---|---|---|---|

| Specific Gravity | g/cm³ | D 792 | 1.15 - 1.17 |

| Tensile Strength | psi | D 638 | 10,000 - 13,500 |

| Tensile Elongation | % | D 638 | 20 - 55 |

| Tensile Modulus | psi | D 638 | 400,000 - 550,000 |

| Compressive Strength | psi | D 695 | 14,000 - 16,500 |

| Compressive Modulus | psi | D 695 | 325,000 - 425,000 |

| Flexural Strength | psi | D 790 | 15,000 - 18,000 |

| Flexural Modulus | psi | D 790 | 400,000 - 520,000 |

| Shear Strength | psi | D 732 | 10,000 - 11,000 |

| Notched Izod Impact | ft.lbs/in. | D 256 | 1.4 - 2.4 |

| Hardness, Rockwell | R | D 785 | 110 - 120 |

| Hardness, Shore | D | D 2240 | 78 - 86 |

| Melting Point | °F | D 3418 | 430 ± 10 |

| Limiting Pressure Velocity | psi-ft/min | 3600 | |

| Coefficient of Linear Thermal Expansion | in./in./°F | D 696 | 5.0 x 10^-5 |

| Deformation Under Load | % | D 621 | 0.5 - 2.6 |

| Deflection Temperature | |||

| 264 psi | °F | D 648 | 200 - 300 |

| 66 psi | °F | D 648 | 300 - 400 |

| Continuous Service Temperature | °F | 230 | |

| Intermittent Service Temperature | °F | 330 | |

| Coefficient of Friction, Dynamic | D 1894 | 0.22 | |

| Water Absorption | |||

| 24 hours | % | D 570 | 0.5 - 0.6 |

| Saturation | % | D 570 | 4.0 - 6.0 |

| Dielectric Strength | v/mil. | D 149 | 500 - 600 |

| Dielectric Constant | |||

| 60 Hz | D 150 | 3.7 | |

| 1000 Hz | D 150 | 3.7 | |

| 1 MHz | D 150 | 3.7 |

Nylon 6

Typical Properties of Nylon 12

Nylon 66

Nylon 66 is similar to nylon 6 however has higher temperature service, stronger tensile, and better resistance to water absorption. When molding into shapes it does however have greater shrinkage so less accuracy in the molded shape. Nylon 66 will be more expensive than nylon 6.

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields