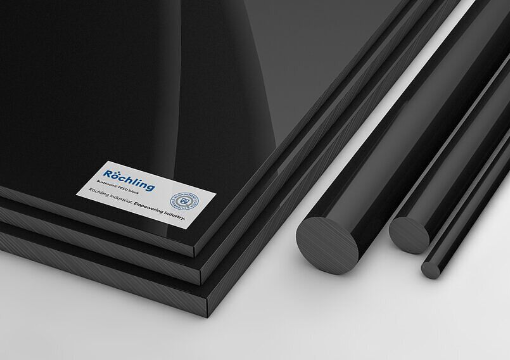

PPSU Polyphenylsulfone, Radel®

DESCRIPTION

Radel® (Polyphenylsulfone – PPSU) is a high performance material that offers better impact resistance and chemical resistance than either Polysulfone or Ultem. It has outstanding resistance to steam, making it an ideal choice for reusable medical and dental instruments and can be used at temperatures approaching 400ºF. It is USP class VI compliant, meaning that through testing there are no harmful reactions or long-term bodily effects when used for an implant.

PRIMARY SOURCE

About the supplier:

Rochling SE & Co. is our primary source of PPSU stock shapes

Characteristics:

- Wide temperature range

- High tensile strength

- Resistant to Steam

- Resistant to acids

- High impact strength

- Easy to machine

- Good dimensional stability

DETAILS:

Rod: 10, 30, 60, 70mm diameter x 1000, 3000, 6000mm length

Sheet Sizes

| Gage, mm | ||||

|---|---|---|---|---|

| 12 | 620 x 1000 | 620 x 3000 | ||

| 15 | 620 x 1000 | 620 x 2000 | ||

| 16 | 620 x 3000 | |||

| 20 | 620 x 1000 | 620 x 3000 | ||

| 25 | 620 x 3000 | |||

| 30 | 500 x 3000 | 620 x 1000 | 620 x 3000 | |

| 35 | ||||

| 40 | 620 x 1000 | 620 x 3000 | ||

| 50 | 500 x 3000 | 620 x 1000 | 620 x 2000 | 620 x 3000 |

Rod Sizes

| Dia, mm | |||

|---|---|---|---|

| 15 | 3000 | ||

| 16 | 1000 | 2000 | 3000 |

| 20 | 1000 | 3000 | |

| 25 | 1000 | 3000 | |

| 30 | 1000 | 3000 | |

| 32 | 1000 | 3000 | |

| 40 | 1000 | 3000 | |

| 45 | 1000 | 3000 | |

| 50 | 3000 | ||

| 60 | 3000 | ||

| Property | Test method | Unit | Guideline value |

|---|---|---|---|

| General properties | |||

| Density | DIN EN ISO 1183-1 | g/cm³ | 1,37 |

| Water absorption | DIN EN ISO 62 | % | 0,7 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | V0 / V0 | |

| Mechanical properties | |||

| Yield stress | DIN EN ISO 527 | MPa | 90 |

| Elongation at break | DIN EN ISO 527 | % | 15 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 2700 |

| Notched impact strength | DIN EN ISO 179 | kJ/m² | 7 |

| Shore hardness | DIN EN ISO 868 | scale D | 85 |

| Property | Test Method | Unit | Guideline Value |

|---|---|---|---|

| Thermal properties | |||

| Melting temperature | ISO 11357-3 | °C | - |

| Glass transition temperature | ISO 11357-3 | °C | 225 |

| Thermal conductivity | DIN 52612-1 | W/(m * K) | 0.18 |

| Thermal capacity | DIN 52612 | kJ/(kg * K) | 1.1 |

| Coefficient of linear thermal expansion | DIN 53752 | 10⁻⁶/K | 55 |

| Service temperature, long term | Average | °C | -50...180 |

| Service temperature, short term (max.) | Average | °C | 220 |

| Heat deflection temperature | DIN EN ISO 75, Verf. A, HDT | °C | 200 |

| Electrical properties | |||

| Dielectric constant | IEC 60250 | 3.9 | |

| Dielectric dissipation factor (50 Hz) | IEC 60250 | 0.002 | |

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | 10¹⁸ |

| Surface resistivity | DIN EN 62631-3-2 | Ω | 10¹⁴ |

| Comparative tracking index | IEC 60112 | 150 | |

| Dielectric strength | IEC 60243 | kV/mm | 25 |

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields