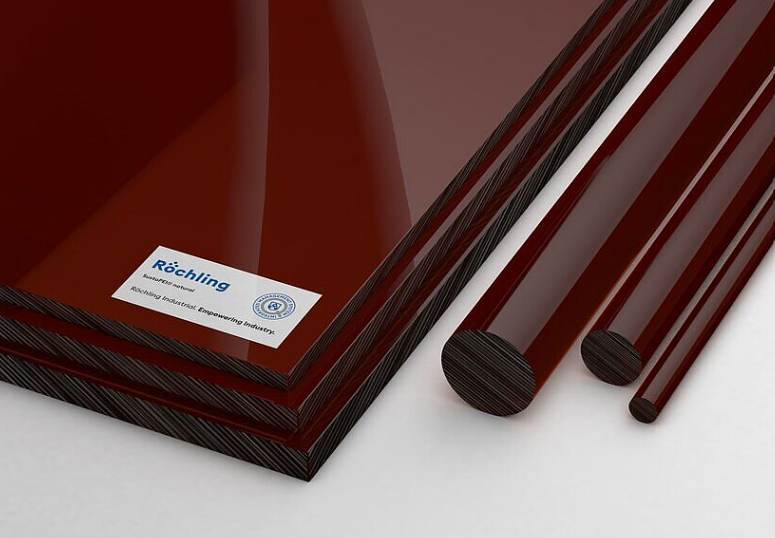

PEI Polyetherimide Ultem®

DESCRIPTION

PEI (polyetherimide) amorphous plastic offers high strength, excellent chemical resistance with a high service temperature. It has a distinct amber-to-transparent coloring. It is used in the automotive industry due to its high heat resistance toughness and weight savings properties over metal. In the same way it is important in the electronics industry. PEI resins are autoclavable and withstand gamma radiation which makes them valuable to the medical industry. The brand Name Ultem is owned by Saudi Basic Industries Corporation and is the most common name used today.

PRIMARY SOURCE

About the supplier:

Rochling SE & Co. is our primary source of PES stock shapes

Characteristics

- High stiffness even at high temperatures

- Low smoke development

- Good resistance against high energy radiation

Industries

- Electrical Industry

- Electronics

- Aerospace

- Healthcare

- Semiconductor Industry

DETAILS:

Rod: 12, 15, 20mm diameter x 1000, 3000mm length

Sheet: 8, 10, 16, 20, 30mm Thick x 500 or 620mm wide x 1000 or 3000mm long

| Test method | Unit | Guideline value | |

|---|---|---|---|

| General properties | |||

| Density | DIN EN ISO 1183-1 | g/cm³ | 1,27 |

| Water absorption | DIN EN ISO 62 | % | 0,5 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | V0 / V0 | |

| Mechanical properties | |||

| Yield stress | DIN EN ISO 527 | MPa | 110 |

| Elongation at break | DIN EN ISO 527 | % | 12 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 3100 |

| Notched impact strength | DIN EN ISO 179 | kJ/m² | 4 |

| Shore hardness | DIN EN ISO 868 | scale D | 86 |

| Thermal properties | |||

| Thermal conductivity | DIN 52612-1 | W/(m * K) | 0,24 |

| Thermal capacity | DIN 52612 | kJ/(kg * K) | 1,10 |

| Coefficient of linear thermal expansion | DIN 53752 | 10⁻⁶/K | 45 |

| Service temperature, long term | Average | °C | -50 ... 170 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Service temperature, short term (max.) | Average | °C | 210 |

| Heat deflection temperature | DIN EN ISO 75, Verf. A, HDT | °C | 200 |

| Electrical properties | |||

| Dielectric constant | IEC 60250 | 3.2 | |

| Dielectric dissipation factor (50 Hz) | IEC 60250 | 0.0015 | |

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | 10¹⁵ |

| Surface resistivity | DIN EN 62631-3-2 | Ω | 10¹⁵ |

| Comparative tracking index | IEC 60112 | 150 | |

| Dielectric strength | IEC 60243 | kV/mm | 30 |

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields