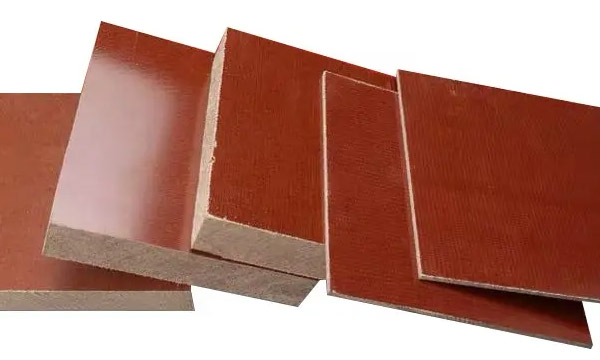

Phenolic (High Pressure Laminates)

DESCRIPTION

Phenolic is a composite material produced by applying heat and pressure to paper or fabric permeated with synthetic resin. Resins used are phenolic, epoxy, melamine and silicone. These are reinforced with paper, fabric, glass fibers or carbon fibers. Phenolics are highly durable and dense and have excellent electrical properties.

Phenolic materials are well-suited for a multitude of industrial applications: electrical insulators, circuit boards, automotive parts and aerospace components. Meyer Plastics offers phenolic in sheet, rod, tube and machining options for parts made to your specification. Give us a call and we will help walk you through specifying the proper solution for your project.

PRIMARY SOURCE

About the supplier:

Norplex Micarta is our primary source for Phenolic sheet rod & tube

Phenolic Resin - Paper Substrates - Sheet Grades

| Grade | NP600 | NP602 | NP605 | NP610 | NP611 | NP611R | |

|---|---|---|---|---|---|---|---|

| rasin | Phenolic | ||||||

| NEMA1 | - | - | - | X | XP** | XP** | |

| color | NA/BK | ||||||

| Sheet Size | Thiknesses Manufactured | ||||||

| 39" x79" | 0.031-4.000 | 0.031-0.500 | 0.016-4.000 | 0.015-4.000 | 0.015-4.000 | ||

| 48" x 120" | 0.031-1.000 | 0.031-1.000 | 0.031-0.500 | 0.010-1.250 | 0.031-1.000 | 0.031-1.000 | |

| 48" x 96" | 0.031-3.000 | 0.031-0.500 | 0.031-0.500 | 0.031-0.125 | 0.031-1.000 | ||

| 48" x 72" | 0.250-0.375 | ||||||

| 48" x 60" | 1.126-4.000 | 1.126-6.000 | 1.126-4000 | 1.126-4000 | |||

| 48" x 72" | 0.250-0.375 | ||||||

| 48" x 60" | 1.126-4.000 | 1.126-6.000 | 1.126-4.000 | 1.126-4.000 | |||

| 48" x 48" | 1.126-4.000 | 1.126-6.000 | 1.125-4.000 | 1.125-4.000 | |||

| 48" x 39" | 1.126-4.000 | 1.126-6.000 | |||||

| Cover Pilles | CA, XB | CA, CH, BK, XB | XB | CA, CH, BK, XB, XF, XC, AL, FC, FD, FE, FG, SU, RC | CA, CH, BK, FC, FD, FE, FG, NF, NG, XB, RC, XE | CA, CH, BK, FC, FD, FE, FG, NF, NG, XB, RC, XE | |

| Press Load Quantity Required |

Able to test and certify NEMA XP up to 0.250″ thick per NEMA LI1

Epoxy Resin - Glass Fabric and Mat Substrates - Sheet Grades

| Grade | MC511A | MC511AF | MC511FR | MC511SN | MC511WR | NP130 | |

|---|---|---|---|---|---|---|---|

| rasin | Epoxy | ||||||

| NEMA1 | G-11 | G-11 | FR-5 | - | - | FR-4 | |

| color | NA/BK | NA | NA | BK | NA | NA,BK | |

| Sheet Size | Thiknesses Manufactured | ||||||

| 48"X120" | 0.187-1.500 | 0.031-3.000 | 0.250-3.000 | 0.118-6.000 | 0.020-3.000 | ||

| 48" x 108" | 0.187-1.500 | 0.187-4000 | 0.250-4.000 | 0.118-4.000 | |||

| 48" x 96" | 0.187-1.500 | 0.031-4.000 | 0.250-4.000 | 0.118-4.000 | 0.062-4.000 | ||

| 48" x 72" | 0.008-1.000 | 0.008-3.500 | 0.250-3.500 | 0.010-1.000 | 0.118-1.000 | 0.005-5.000 | |

| 48" x 60" | 1.126-4.000 | 0.250-4.000 | 0.118-4.000 | ||||

| 48" x 54" | 0.187-6.000 | 0.250-6.000 | 0.118-4.000 | ||||

| 48" x 48" | 1.126-6.000 | 1.126-6.000 | 0.250-6.000 | 0.118-6.000 | 1.126-4.000 | ||

| 48" x 36" | 0.187-4.000 | 0.187-6.000 | 0.250-6.000 | 0.187-6.000 | 0.187-6.000 | ||

| Press Load Quantity Required | X (48"X120") | X (48"X120") | X (48"X120") | X (48"X120") |

Nylon 6

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields