POM-Acetal-Polyoxymethylene

DESCRIPTION

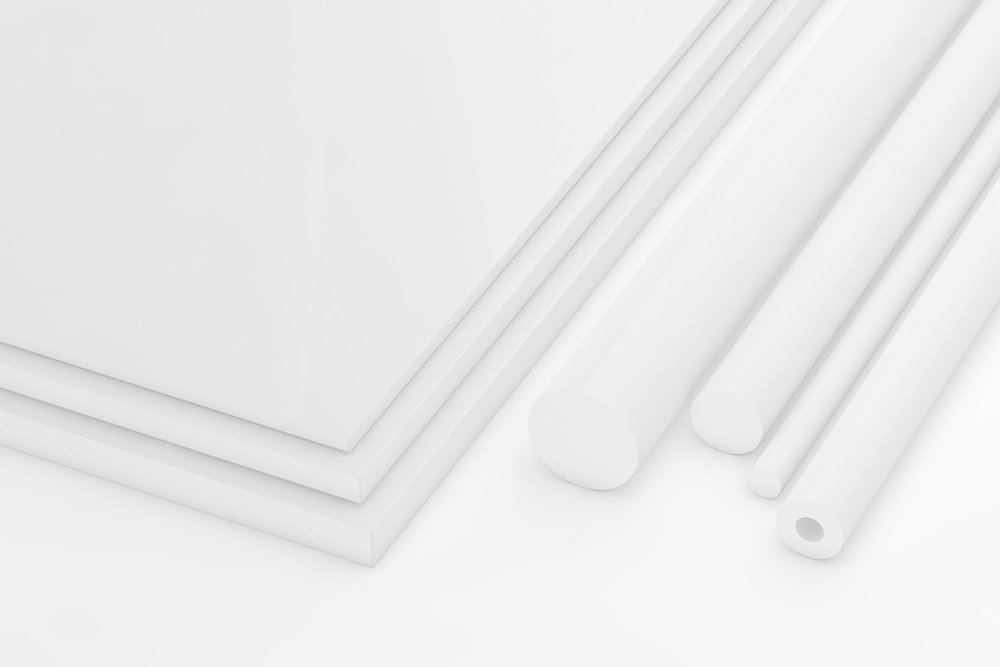

Acetal plastic (POM) is a semi-crystalline thermoplastic that is based on the formaldehyde molecule. It is used to make mechanical gears, electrical components, automotive products, sports equipment, medical products and food equipment, due to its stability, stiffness, low friction, and natural FDA properties. The stability and density make it one of the easiest plastics to machine with accurate results. Acetal plastic is available in homopolymer (POM-H) and copolymer (POM-C) options. Homopolymer acetal is commonly referred to by the trade name Delrin®, a product from DuPont de Nemours, and is available in the shape of plates or sheets, rods, and tubes. Different Additives to Acetal provide enhanced properties for improved bearing, stability, tensile strength, stiffness, and metal detectability. Meyer Plastics stocks an array of Acetal shapes and is happy to source your specific needs.

PRIMARY SOURCE

About the supplier:

Rochling SE & Co. is our primary source of Acetal stock shapes. Rochling Homopolymer Acetal is branded under the name Sustarin H and their Copolymer Acetal is branded under the name of Sustarin C.

NOTE

Let Meyer Plastics 3D print your next new project or duplicate a hard-to-find part. We have the ability to reverse

engineer, simplify, and add various improvements to your current part design. Not only that but we will graciously

provide these services just for the opportunity to service your business. Acetal is only one of the many plastics we can 3D Print.

Acetal Copolymer

- High chemical resistance

- High dimensional stability

- Low moisture absorption

- Excellent sliding properties

- High abrasion resistance

- Ideal combination of strength, stiffness and toughness

- Little tendency to creep

- Good machinability

- Favorable electrical and dielectric behavior

Acetal Homopolymer

- High strength of shape

- Low moisture absorption

- Good wear resistance

- High mechanical strength, stiffness and toughness

- High creep resistance

- Good machinability

Sustarin C – POM C Properties

| Property | Test Method | Unit | Guideline Value |

|---|---|---|---|

| Density | ASTM D792 | g/cm³ | 1.41 |

| Water Absorption 24 hours | ASTM D570 | % | 0.2 |

| Dissipation Factor | ASTM D150 | 1MHz | 0.004 |

| Water Absorption Saturation | ASTM D570 | % | 0.9 |

| Mechanical Properties | |||

| Hardness | ASTM D2240 | Shore D | 85 |

| Tensile Strength at yield 73°F | ASTM D638 | psi | 9500 |

| Tensile Modulus | ASTM D638 | psi | 400000 |

| Elongation at Break | ASTM D638 | % | 40 |

| Flexural Strength | ASTM D790 | psi | 12000 |

| Flexural Modulus | ASTM D790 | psi | 400000 |

| Compressive Strength | ASTM D695 | psi | 15000 |

| Rockwell Hardness | ASTM D785 | 88 | |

| Rockwell Hardness | ASTM D785 | R | 120 |

| Shear Strength | ASTM D732 | psi | 8000 |

| Izod Impact, Notched | ASTM D256 | ft-lb/in | 1.2 |

| Coefficient of Friction, Dynamic | 0.21 | ||

| Thermal Properties | |||

| Thermal Conductivity | in/hr/ft²/°F | 1.6 | |

| Coefficient of Linear Thermal Expansion | ASTM D696 | in/in/°F x 10-5 | 5.5 |

| Melting Point | °F | 330 | |

| Continuous Service Temperature, Air | °F | 180 | |

| Deflection Temperature at 1.8Mpa (264psi) | ASTM D648 | °F | 225 |

| Deflection Temperature at 1.8Mpa (66psi) | ASTM D648 | °F | 320 |

| Flammability, UL94 | 1/8 inch | HB | |

| Electrical Properties | |||

| Dielectric constant | ASTM D150 | 1MHz | 3.8 |

| Dielectric strength | ASTM D149 | V/mil | 450 |

| Surface resistivity | ASTM D257 | Ohm/cm | 10¹⁶ |

| Compliance Properties | |||

| FDA | Yes | ||

| NSF | No | ||

| USDA | Yes |

Valve

for a ball valve made of Sustarin® rod/semi-finished Acetal

Housing component

for medical equipment machined from Sustarin® C (Acetal Copolymer)

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields