Mold Making

DESCRIPTION

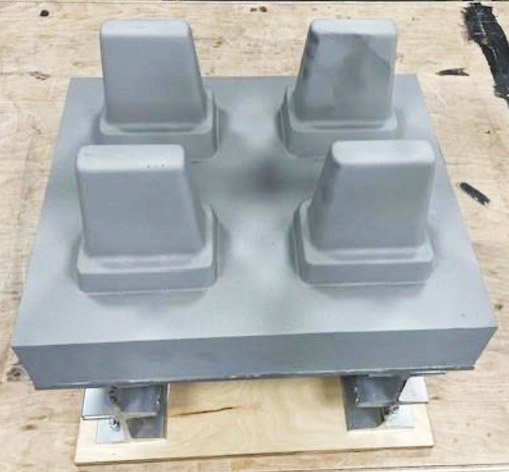

Meyer Plastics manufacturing processes typically require some form of tooling to make a quality plastic part. Our thermoformed parts will require a mold to form the plastic sheet with vacuum. Our best molds are cast aluminum water temperature controlled. We do however prototype sample parts with wood or Renshape machined patterns. These can be used for short production runs but do sacrifice detail and accuracy in part-to-part consistency. Typically, we will machine a CNC routing trim fixture using the same geometric model that was used for the mold. It is not unusual to need a plug assist or draw box in addition to the mold to assist in forming a part with uniform wall thickness over a mold with deep geometry.

Other tooling that we use at Meyer Plastics includes cooling fixtures for line bending, glue alignment fixtures, hand routing fixtures, staging racks, and quality control gauges. Dor the most part these are made in our own shop benefiting the customer with their low cost. Our tool makers are adept at cabinet making, mold making, including the use of laminating and casting resins.

Mold Storage

each tool is identified and specified in our ERP database, tracking location, and service life.5 axis CNC trim fixture

Machined from CAD model of the part. Holds formed part with vacuum during trim cycle.Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields