ACRYLIC-Methyl Methacrylate (MMA, Plexiglas®, Lucite®, Acrylite®)

DESCRIPTION

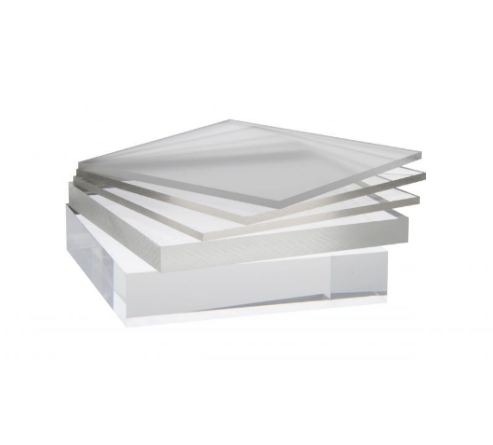

Acrylic sheet exhibits glass-like qualities outstanding versatility with significant durability. At half the weight and many times, the impact resistance of glass, it is a common replacement for window glazing, picture frames, museum displays, and retail POP displays. It is also used in the sign and graphic market, direct digitally printing all sorts of signage. Clear sheet makes up most of the acrylic consumption, and it is also available in a mirid of colors, textures, sizes, and formulations for enhanced properties. Acrylic can be easily thermoformed and bonds well using solvents or other adhesive formulations.

Acrylic sheet is available made by the extrusion process or by the casting process. In most cases the sheet can be used interchangeably. Acrylic sheet made with the extrusion process will have very tight thickness tolerance but has less impact strength than cast sheet. Acrylic sheet made with the casting process while varying more in thickness up to 10%, is more scratch resistant, higher molecular weight, providing for more strength than extruded sheet. Meyer Plastics stocks a significant inventory of Acrylic Sheet and is happy to supply or source your specific needs. We also fabricate with saws, routers, lasers, polishers and line benders to create parts or displays to your specific design.

PRIMARY SOURCE

About the supplier:

Polyvantis Sanford, LLC, is a primary supplier of Acrylite® sheet

About the supplier:

Margacipta-Titan is also a primary supplier

Acrylic Clear Extruded Sheet

Clear extruded acrylic sheet is lighter weight and stronger than glass. It is also clearer than glass, and more UV resistant. Extruded acrylic sheet is made by feeding hot liquid monomer through an extrusion die and a series of rollers that squeeze the cooling monomer into the desired sheet gage. The final set of rollers imparts a high polish or texture with protection films applied at the end. Extruded acrylic can be made to tight thickness tolerance varying only +/-.002 inches.

| Gage | Sheet Size |

|---|---|

| 0.06 | 48 x 96 |

| .090" | 60 x 96 |

| 0.118 | 72 x 96 |

| 0.15 | 51 x 100 |

| 0.177 | 48 x 120 |

| 0.22 | 60 x 120 |

| 0.236 | 72 x 120 |

| 0.472 | |

| 0.708 | |

| 0.944 |

Acrylic Clear Cast Sheet

Acrylic clear cast sheet is higher in molecular weight than extruded sheet providing for higher impact strength. It is processed by pouring the liquid monomer between glass plates using a rubber gasket for an edge seal. The plates are baked and allowed to cool gradually and then separated leaving cured acrylic sheets. The sheets are then trimmed, and paper or plastic film applied to each side. Cast acrylic has the advantage of being a batch process rather than continuous, so color change can be performed on smaller quantities. Where the extruded process is very precise in thickness tolerance, cast acrylic sheet thickness may vary across the sheet.

| Thickness | Sheet SIzes |

|---|---|

| 0.06 | 48 x 72 |

| 0.08 | 48 x 96 |

| .090" | 60 x 96 |

| 0.118 | 72 x 96 |

| 0.15 | 51 x 100 |

| 0.177 | 48 x 120 |

| 0.22 | 60 x 120 |

| 0.236 | 72 x 120 |

| 0.472 | |

| 0.708 | |

| 0.944 |

Other Acrylic Sheet Offerings:

Textured Acrylic Sheet: P95, This acrylic sheet has one side that has been treated with a textured surface to provide a frosted like appearance.

Museum Grade (Archive) Acrylic Sheet: This sheet has been formulated to screen out harmful UV rays to protect artwork or documents for display.

LED Acrylic Sheet: This acrylic is formulated to optimize LED lighted displays.

Toughened Acrylic Sheet, Acrylite® Resist: This acrylic sheet is blended to be a tougher sheet option for retail displays that better handle the daily impacts. It also will more likely arrive abuse from harsh freight handling.

Scratch Resistant Coated Acrylic: Acrylite® AR one or Two sided coated will provide years of scratch free use particularly effective for a retail environment.

Lucite is a trademark of Plaskolite

Cast Acrylic assembly chamber for an industrial flocking machine.

Gravity Feed Chute: CNC routed panels, line bent inner panels, then glued together.

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields