Gatorfoam®

DESCRIPTION

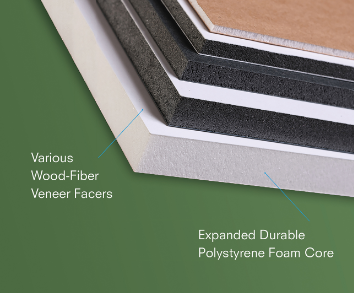

GATORFOAM® is an extremely stiff lightweight foamboard with resin-impregnated paper liners on both sides and a polystyrene foam core. Due to its great rigidity and flatness, as well as the availability of thicknesses of up to 25 mm, GATORFOAM® is ideally suited for displays and 3D applications (e.g. letterings), for demanding lamination options as well as decorative applications and décor in interior design.

The material’s bright white surface guarantees high-quality direct printing results and exceptional image quality. Simple mechanical processing is possible with standard tools for processing wood and plastic. Gatorfoam is a composite sheet with a polystyrene foam core with laminated resin impregnated liners on each side.

PRIMARY SOURCE

About the supplier:

3A Composites is our primary sources of Gatorfoam® stock sheet

Attributes:

- High rigidity and flatness

- Ideal for displays and 3D applications

- High quality direct printing results

- Simple mechanical processing

Applications:

Displays (POS/POP), Signage, Lettering, Shop design, Shop window decoration, Exhibition design, Exhibition technology, Model making, Craft supplies

Colors-Thickness-Sizes

| Gage (mm) | Gage (mm) | Gage (mm) | Width x Length | Width x Length | |

|---|---|---|---|---|---|

| White | 5 | 10 | 25 | 48 x 96 | 60 x 120 |

| Black | 5 | 10 | 48 x 96 |

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields