PVC Foam (Sintra®, Celtec®, Lamicor®, Palite®)

DESCRIPTION

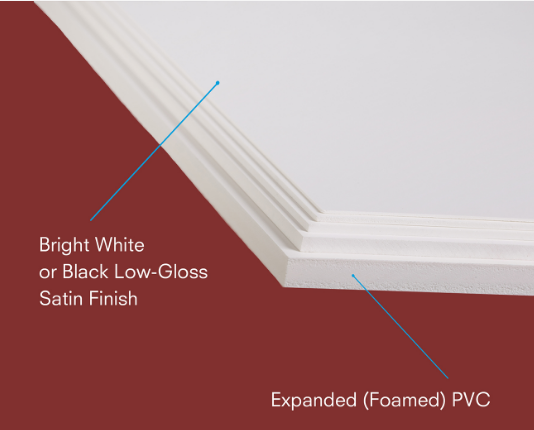

PVC board provides a premium surface with a bright white low gloss with satin finish for high quality printing results. It has superior durability for more demanding mounting or fabricating applications over light weight foam board substrates. Mold it, shape it, form it, cut it, it has excellent dent & scratch resistance making it the perfect selection for almost any project. PVC Foam sheet is resistant to many chemicals, and weatherable in most situations. Dark colors can absorb UV heat and warp so dark colors are not recommended for exterior applications. Care should also be taken within large orders of colored sheet to ensure color continuity through the entire order as well as repeat orders for matching color from batch to batch.

Meyer Plastics has a long history of supplying the graphic industry with their PVC Foam needs. We stock significant supplies of PVC Foam sheet and have experience supplying truck loads for large printing jobs.

Material Composition

PVC Foam is comprised of moderately expanded, closed-cell polyvinyl chloride (PVC) in a homogenous sheet with a low-gloss satin finish.

PRIMARY SOURCE

About the supplier:

Palram Americas, is a primary source of PVC Foam sheet.

About the supplier:

3A Composites, is also a primary source of PVC Foam sheet

PVC Foam Properties

- Consistent bright white surface and sheet thickness

- Superior dent and scratch resistance

- Lightweight yet rigid and durable

- Heat formable for dramatic, 3-dimensional displays.

- Excellent chemical resistance

- Easily machinable using wood and foam board fabrication techniques.

- Available in a wide range of thicknesses & sheet sizes

- Gauges 10mm+ recommended for exterior signage.

- Self-extinguishing; Class A Fire Rating (ASTM E-84) in gauges 3mm and less

- UL Recognized

| Gage | 48 x 96 | 48 x 120 | 50 x 100 | 60 x 120 | 1M x 96 | 2M x 120 |

|---|---|---|---|---|---|---|

| 1mm | W | |||||

| 2mm | W | W | ||||

| 3mm | W B | W B | W | W B | W | W |

| 6mm | W B | W B | W | W B | W | |

| 10mm | W | W | ||||

| 12.7mm | W | W |

Machine head mount

Geometric ribs were designed into the part for rigidity and part simplification.

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields