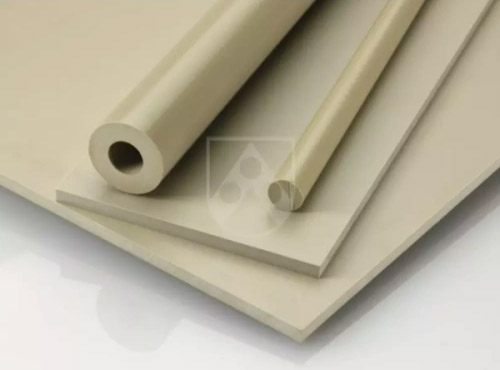

PEEK-Polyetheretherketone (PEK)

DESCRIPTION

PEEK is a semicrystalline thermoplastic with excellent mechanical strength and chemical resistance properties that are retained to high temperatures. It has a glass transition temperature of around 143 °C (289 °F). Depending on the way it is made, some grades have a useful operating temperature of up to 250 °C (482 °F).

PEEK is used to fabricate items used in demanding harsh applications, including bearings, piston parts, pumps, compressor plate valves that are used in challenging environments. Due to the higher performance this plastic provides it is also a fairly expensive plastic so call us so we can help determine just what you need.

Peek Characteristics:

- High Temperature Performance, 480 continual use

- Good dimensional stability

- Superior Chemical resistance

- Superior wear & friction resistance

- High mechanical strength

- Superior resistance to gamma and X-rays

- High vacuum applications

- Good radiation resistance

- Good machinability

PRIMARY SOURCE

About the supplier:

Rochling, SE, Co. is our primary source for standard PEEK shapes.

Rochling uses the brand name SustaPEEK to name their Peek products

| Property | Test Method | Unit | Guideline Value |

|---|---|---|---|

| Thermal Conductivity | in/hr/ft²/°F | 1.73 | |

| Coefficient of Linear Thermal Expansion | ASTM D696 | in/in/°F x 10⁻⁵ | 2.6 |

| Melting Point | ASTM D789 | °F | 630 |

| Continuous Service Temperature, Air | °F | 480 | |

| Deflection Temperature at 1.8Mpa (264psi) | ASTM D648 | °F | 320 |

| Deflection Temperature at 1.8Mpa (66psi) | ASTM D648 | °F | 360 |

| Flammability, UL94 | 1/8 inch | V-0 |

Request a Quote

Meyer Plastics is a multifunctional plastic supplier combining the best parts of plastic distribution with excellent plastic manufacturing. Let’s get to work! Connect with us using this form, or tell us more about your upcoming project, and we will be in touch shortly.

Please, No Solicitations. Thank you.

"*" indicates required fields